Blog

If you purchased an Avocado this year with a sticker on it proclaiming, “Produce of California” or “Produce of Mexico,” there is a good chance it came from a ripening facility being operated by an Airixa refrigeration control system.

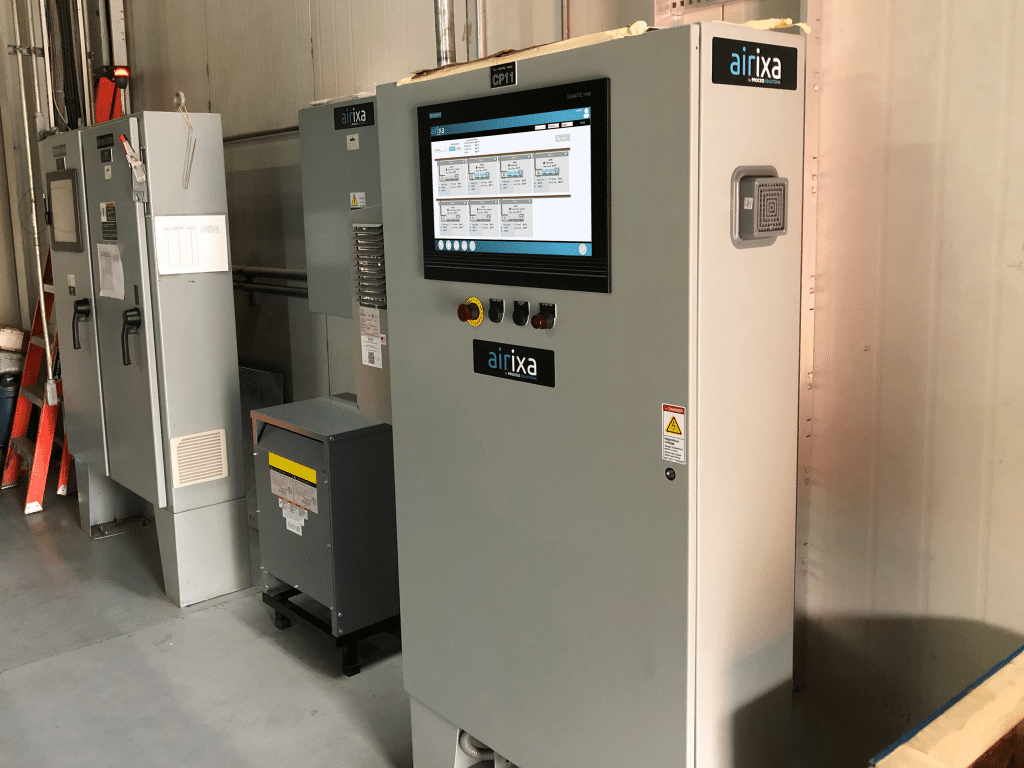

Process Solutions recently deployed a team of engineers to Mexico to commission new Airixa refrigeration control systems that were installed in two separate Avocado processing and storage facilities.

The first avocado facility was stocked with millions of dollars worth of product, which meant the system could not be down for more than 3 hours. To minimize downtime, we developed wiring harnesses that included mating connectors that plugged directly into the existing control system wiring. By using the wiring harnesses, Process Solutions’ engineering team was able to install the entire new system in a single work day.

In addition to the PLC components, the new Airixa system included a combination of 67 variable frequency drives, 7 RTU to Modbus converters, and a fiber-optic cable to connect the system between two remote locations at the facility.

Once installation was complete, Airixa began operating 2 separate engine rooms with 7 refrigeration compressors, 6 condensers, 10 suction accumulators, and 2 Freon detectors, along with 15 cooler rooms housing 57 evaporators.

The second Airixa system we installed in Mexico was considerably smaller; however, it still provided a significant boost to the efficiency of the plant’s operations. After replacing the existing legacy control units, Airixa took over operation of the facility’s engine room, which included a chiller and glycol circuit, along with 3 refrigeration compressors, 5 condensers, and 4 cooler rooms with 14 air units. In order to run all of these machines, the Airixa system was equipped with 30 Siemens G120 series VFDs.

Airixa is a technology platform for the control of industrial refrigeration systems and energy management. With Airixa, companies can reduce peak energy demands and run their facility at optimal efficiency without sacrificing operational performance. To learn more about Airixa, please visit www.processsolutions.com/airixa.