Machine Monitoring Platform

Leverage real-time data from your equipment and processes to gain insight into system performance, health, and product quality.

Automated Machine Data Collection

You're just a few clicks away from real-time production insights.

DAQuery provides automated machine data collection and production analytics to deliver insights into system health and performance through detailed reports, live trends, KPIs, and customizable dashboards. With a simple plug-and-play setup process, it only takes minutes to connect DAQuery to your equipment and start making data-driven improvements to your operations.

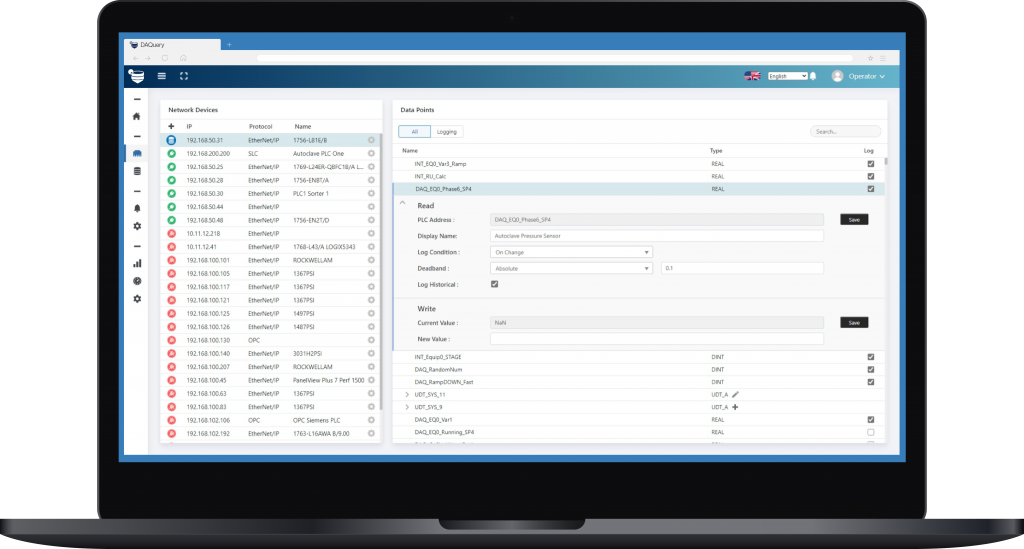

Connect the provided edge device to your network via Ethernet, and DAQuery will automatically discover all available equipment and begin logging data in real-time. The setup takes just minutes to complete, and doesn’t require any specialized training or help from a software engineer.

Using a broad range of machine protocols such as Ethernet/IP, OPC, and Modbus, you can connect and monitor any piece of equipment all from one place simultaneously.

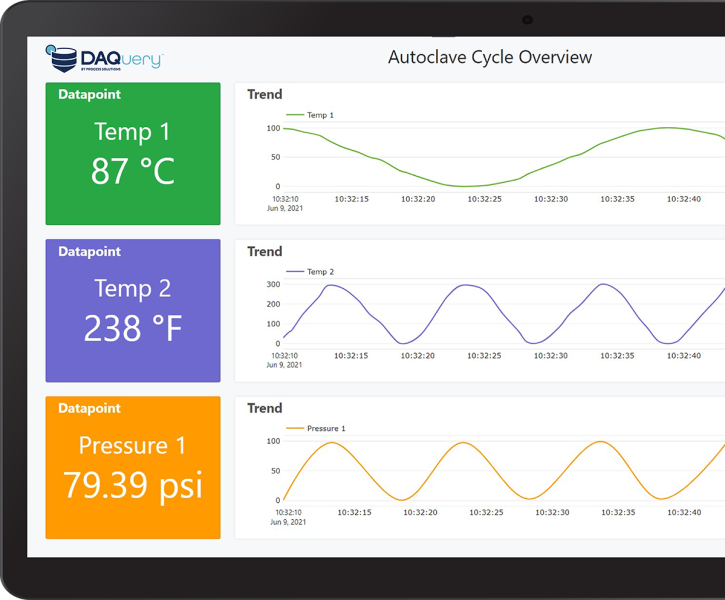

Collect and analyze real-time machine data in various forms, including reports, KPIs, live trends, alarms, and customizable dashboards.

Quick and easy to navigate interface that removes the noise to help put focus on the data without compromising on power and functionality.

Real-Time Production Visibility

Reduce downtime and pinpoint bottlenecks in your operations.

Monitor the performance of your equipment and processes in real-time to discover where inefficiencies and waste are occurring in your operations. Make extended downtime a thing of the past with instant alerts and downtime tracking to help quickly diagnose problems and get your equipment back up and running. Display live and historical data with trends, tables, and production reports for in-depth analysis to help make better-informed decisions.

Flexible Browser-Based Application

Scalable and lightweight software accessible from any internet capable device.

Display dashboards, trends, and live-data feeds on multiple screens across your facility with DAQuery’s browser-based application. Once displayed, DAQuery’s simple and intuitive interface provides ease of use to keep the focus on your data while maintaining the power and capability needed for in-depth analysis. No complex set-up process or time wasted navigating menus.

All The Apps You'll Need

Tools to keep you informed on every aspect of your operations

Custom Dashboards

Combine your charts, tables, images and more within a dashboard and display it on multiple screens across your facility.

Events & Alarms

Reduce downtime and assign the right people to be alerted immediately when user-defined events occur.

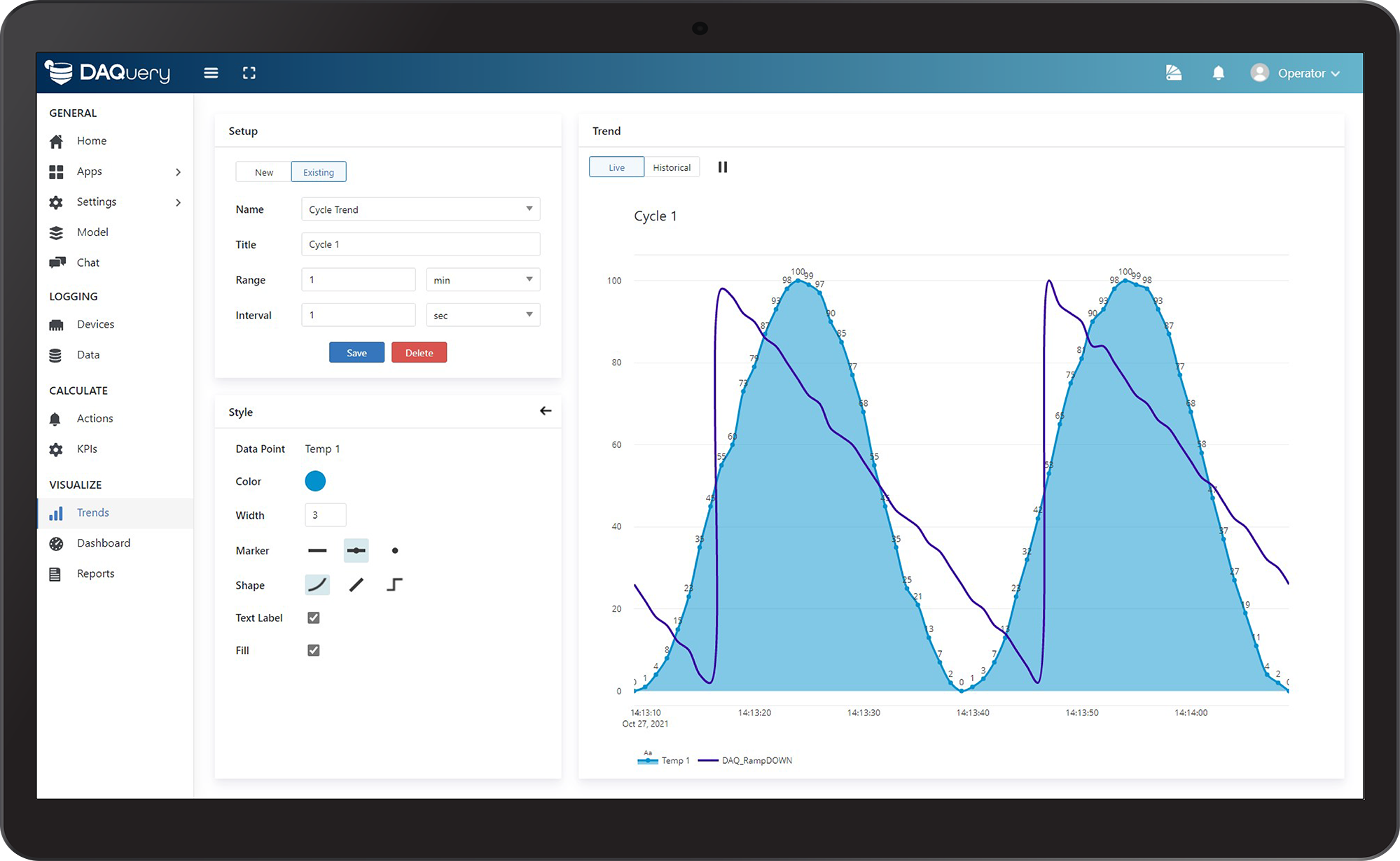

Live Trends

Increase production visibility and discover bottlenecks with custom trends displaying real-time machine data.

Reports

Be informed with detailed reports, including downtime, production, batch, and more.

Auditing

CFR 21.11 compliance for demonstrable traceability and record keeping to pass your next audit.

Integrations

Integrate with existing ERP/MES systems to record data across your operations.

Full-Service Remote System Setup

Let our team of DAQuery developers do the setup work for you and remotely configure your system with the settings, device connections, reports, dashboards, and alarms you need, so you can start monitoring your production process the moment your system arrives. Full-service remote system set-up is available with all DAQuery plans for a flat rate of $1,990.

No Monthly or Annual License Fees

You will never be required to pay monthly or annual license fees for your DAQuery system. Simply select the features that fit your goals, the number of device connections you need, and with systems starting at just $2,990, you will only have to make one small payment for the lifetime of your system.