Instrumentation

Integration &

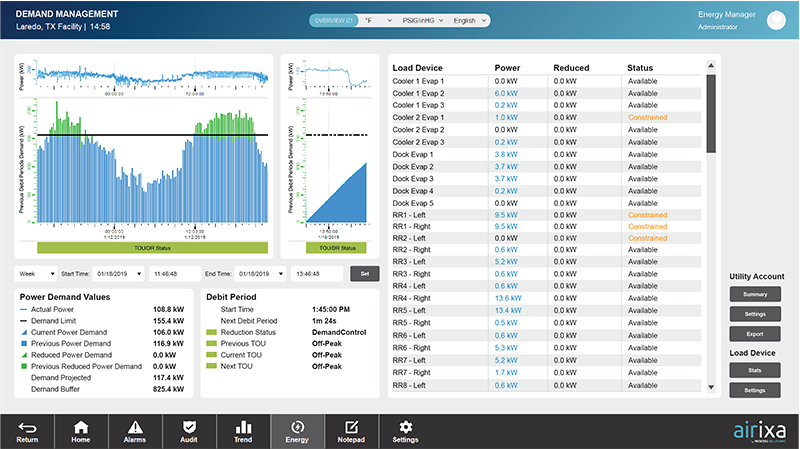

Data Monitoring

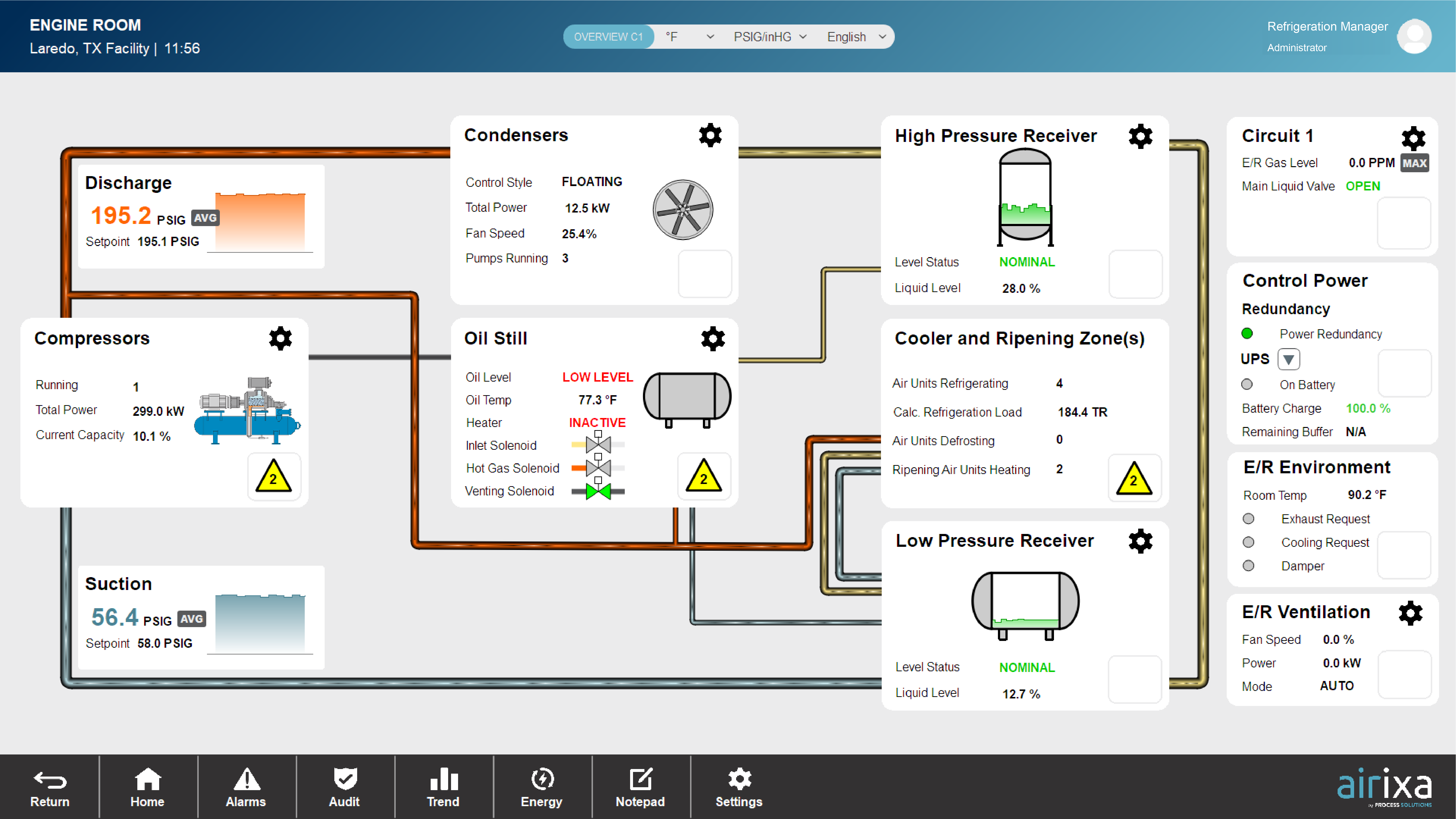

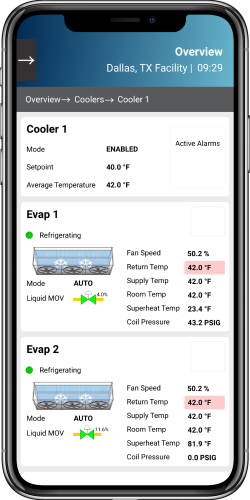

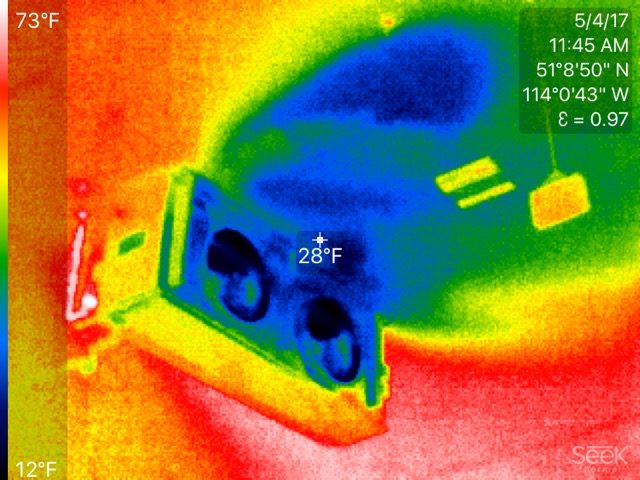

Refrigeration systems that contain Ammonia, Freon, and other refrigerants require constant monitoring for leaks to ensure the safety of workers and the environment. Airixa integrates with a variety of system instrumentation, such as Freon and Ammonia detectors, alarming strobes, and horns to provide immediate alerts in the event of a leak. Airixa also integrates with CO2, humidity, pressure, and temperature sensors to provide real-time information about the environmental conditions in and outside of your facility and ripening rooms.