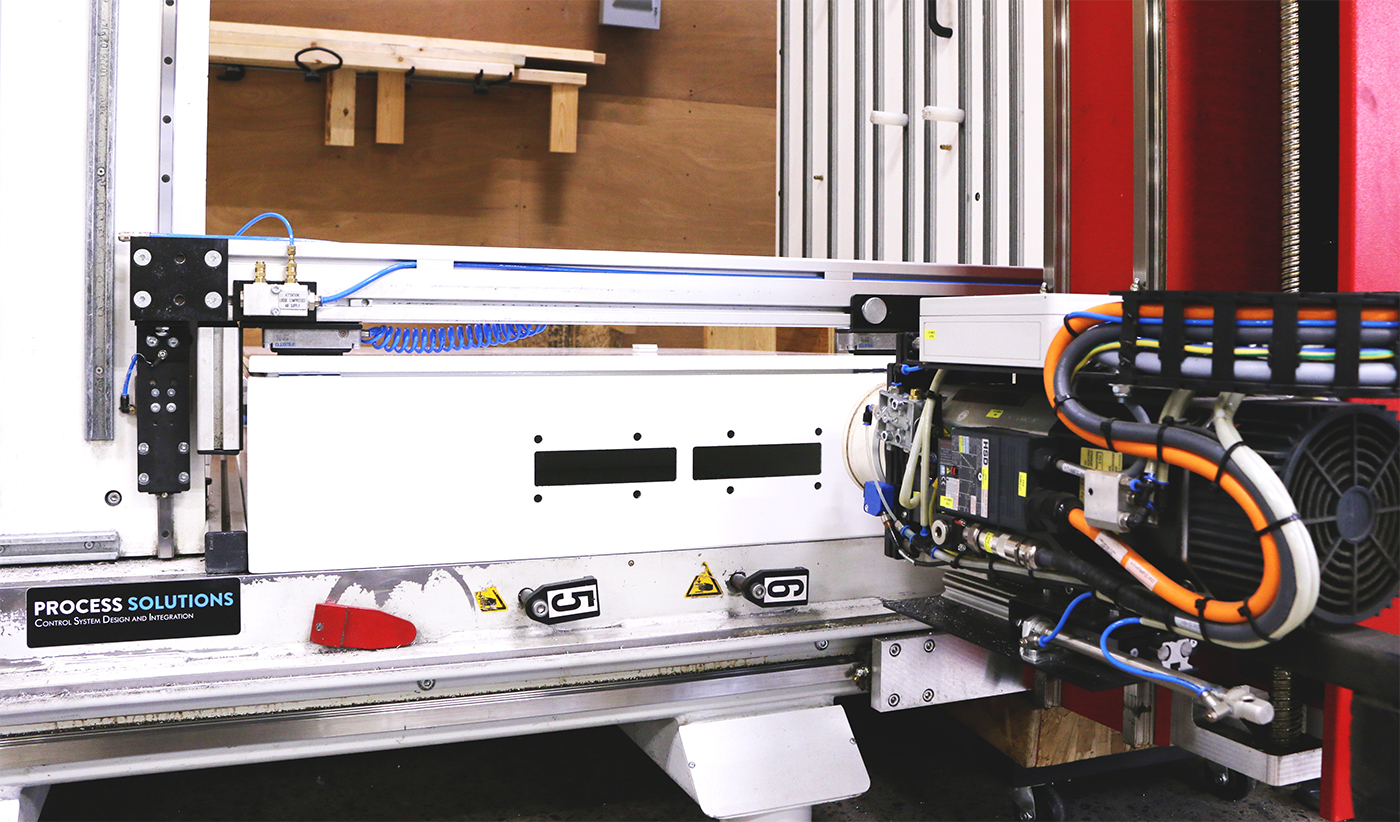

Custom Control Panel Design & Fabrication

Since 1987, Process Solutions has designed and built custom control panels for a wide range of industries and applications. Send us your requirements, and our team of engineers will work with you to design the optimal control solution for your application.

Let's Talk About Your Project

Custom Control Solutions For Your Application

Control Panel Design

Engineering Services

Control Panel Build

UL Certified Control Panel Shop

Process Solutions is a UL certified control panel shop specializing in the design and build of UL 508A-listed custom control panels, as well as UL 698A, 1203, and 1604 control panels designated for hazardous locations. Process Solutions is audited by UL multiple times per year based on the number of panels we build to ensure compliance.

OEM & Build-To-Print Control Panel Manufacturing

Building custom or pre-designed control panels for OEMs is a particular specialty. Our build-to-print control panel services include engineer-led design reviews to ensure compliance with industry standards and to offer recommendations for improved cost and manufacturing efficiency. We also provide parts purchasing, control panel manufacturing, documentation, thorough testing, and commissioning.

Commitment to Quality

Rockwell Automation

System Integrator

Partner

Siemens

Solution Partner

Automation

Aveva

Certified

Systems Integrator

Ignition

Registered System

Integrator