PLC Programming

Process Solutions provides complete PLC control system services, including PLC programming, control panel fabrication, system migration, integration, and technical support.

OVERVIEW

PLC Solutions For Process Automation

Process Solutions provides PLC systems designed to help our clients gain greater control of their machines and processes. Our engineering team has hundreds of combined years of experience working with industry-leading PLC platforms, including Rockwell, Siemens, GE, and Schneider Electric. We develop each of our PLC programs with modular code blocks that help reduce development time and have been proven in the field over thousands of installations. Our code blocks also simplify the process of modifying programs for additional functionality or future expansion.

IEC 61131-3 Compliance

Our team of engineers are proficient in IEC 61131-3 standards for PLC programming.

Modular Code Blocks

We minimize development time through the use of modular code blocks that have been proven in the field.

UL508A Panel Shop

Specializing in the design and build of custom UL-listed control panels suited for PLC and HMI control systems.

PLC Programming Methods

Process Solutions can employ a variety of programming methods depending on the intended application and the overall goals of our clients. Each of our PLC programs adhere to IEC 61131-3 standards and can utilize modular code blocks for quicker development time and greater flexibility for modifications and future expansion efforts.

- Ladder Logic

- Function Block Diagram

- Structured Text

- Instruction List

- Sequential Flow Charts

PLC Migration and Upgrades

As legacy PLC-5 control systems and other outdated PLCs continue to age, it becomes harder to find replacement parts and system maintenance becomes increasingly more expensive. Migrating to a modern PLC platform offers significant improvements to OEE (Overall Equipment Effectiveness), system reliability, parts availability, support, and efficiency.

When performing PLC upgrade services, we do our best to reduce downtime and costs by developing a thorough migration strategy using either a phased or total replacement approach. Additionally, we work to maintain the existing field wiring and enclosure footprint whenever possible. Our PLC migration services also include updating all system schematics, converting existing logic and programs to the new PLC platform, and performing thorough testing to ensure full operation and compatibility.

When performing PLC upgrade services, we do our best to reduce downtime and costs by developing a thorough migration strategy using either a phased or total replacement approach. Additionally, we work to maintain the existing field wiring and enclosure footprint whenever possible. Our PLC migration services also include updating all system schematics, converting existing logic and programs to the new PLC platform, and performing thorough testing to ensure full operation and compatibility.

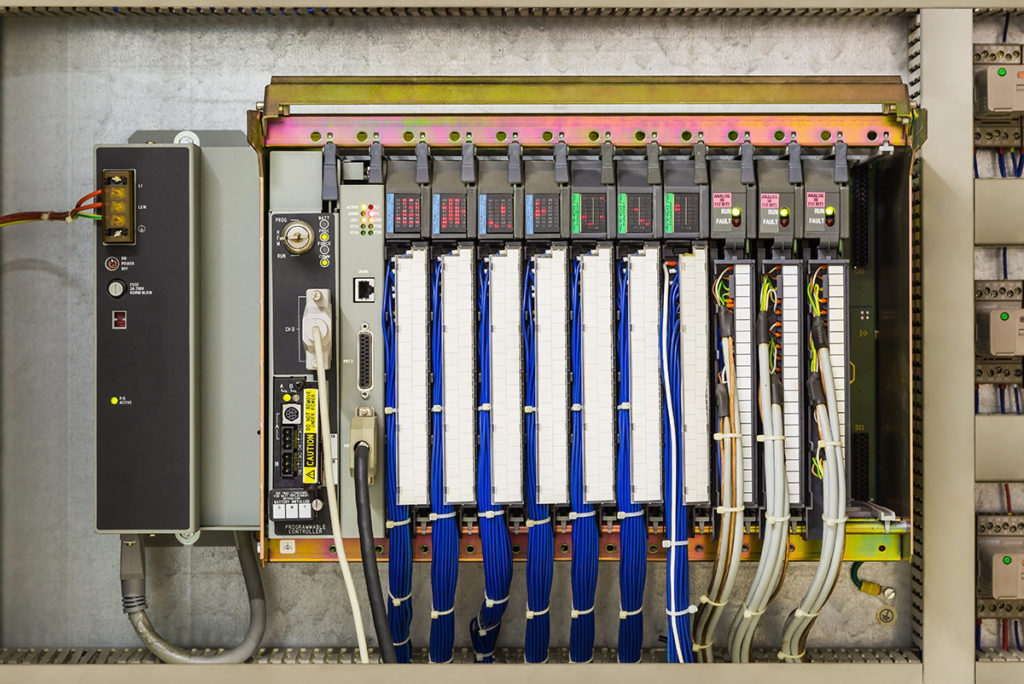

PLC Control Panel Manufacturing

Process Solutions builds PLC control panels designed to meet your required specifications and our standards for quality, safety, and reliability. We offer UL 508A and UL 698A control panel listing, and we thoroughly test every panel we build to ensure proper operation.

In addition to manufacturing PLC control panels, our capabilities also include PLC integration with both new and existing equipment and software systems, such as HMI displays and SCADA systems, as well as robot, vision, machine monitoring, and MES systems.

In addition to manufacturing PLC control panels, our capabilities also include PLC integration with both new and existing equipment and software systems, such as HMI displays and SCADA systems, as well as robot, vision, machine monitoring, and MES systems.

Rockwell Automation

System Integrator

Partner

Siemens

Solution Partner

Automation

Aveva

Certified

Systems Integrator

Ignition

Registered System

Integrator

Let's Get Started

Contact us today to discuss your project or learn more about our products and services.