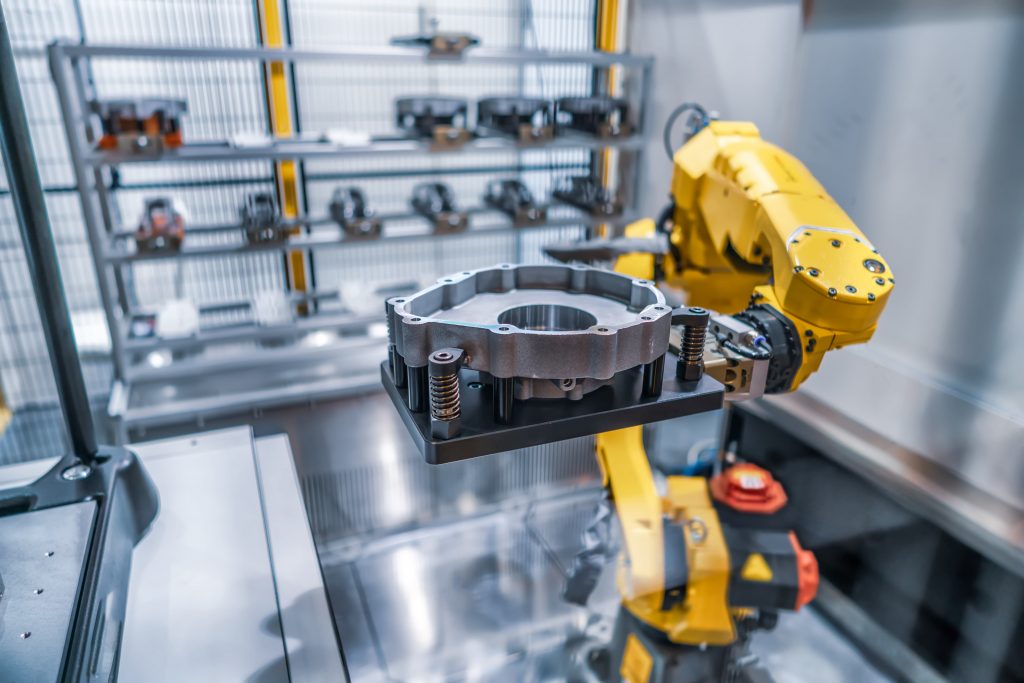

Robot Cell Layout & End-of-Arm Tooling

Process Solutions’ team of experienced engineers design efficient robot work cell layouts to help manufacturers realize optimal production output from their robots and equipment. We also provide custom end-of-arm tooling design and build services to enable robots to perform specific tasks. Additional services include reach analysis, robot sizing, and proof of concept demonstrations.