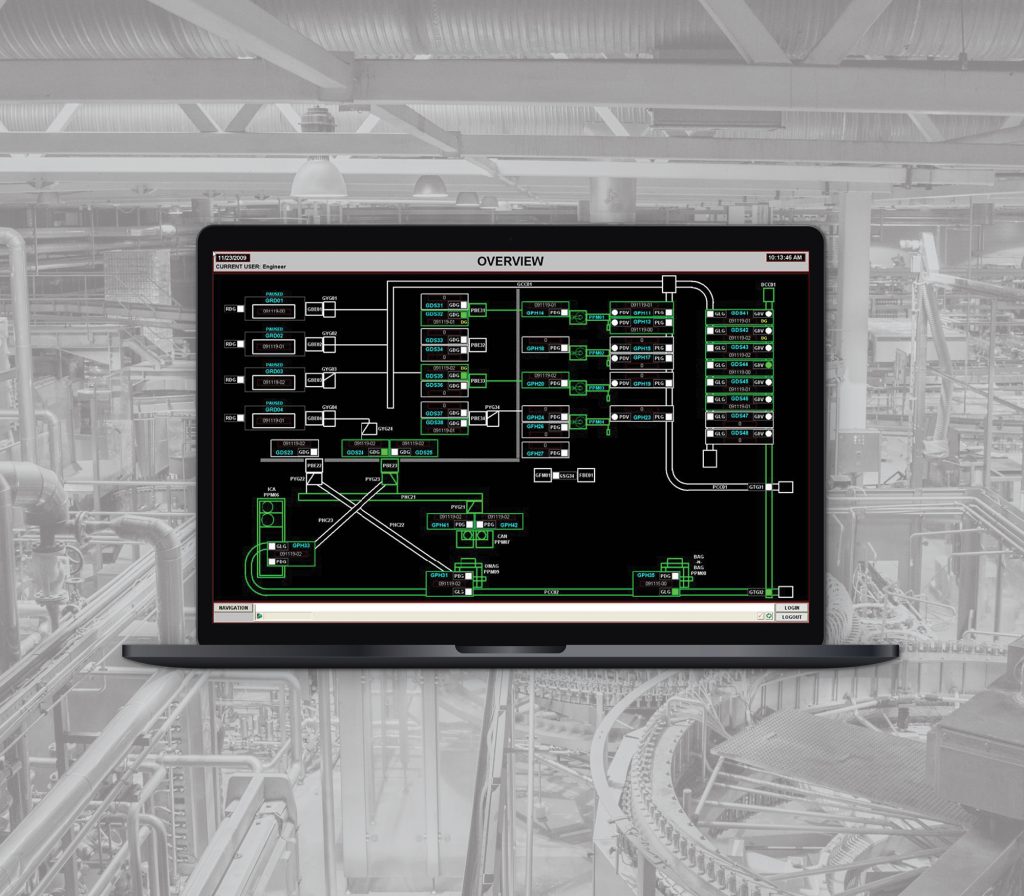

SCADA System Integration

Process Solutions is a SCADA systems integrator with over 33 years of experience in the design, build, and integration of solutions that improve operational awareness and efficiency through advanced alarming, real-time data visualization, supervisory control, and remote communication capabilities.