What Sets Us Apart

With hundreds of control systems integrators to choose from, these are some of the reasons why Process Solutions is the right choice for your project.

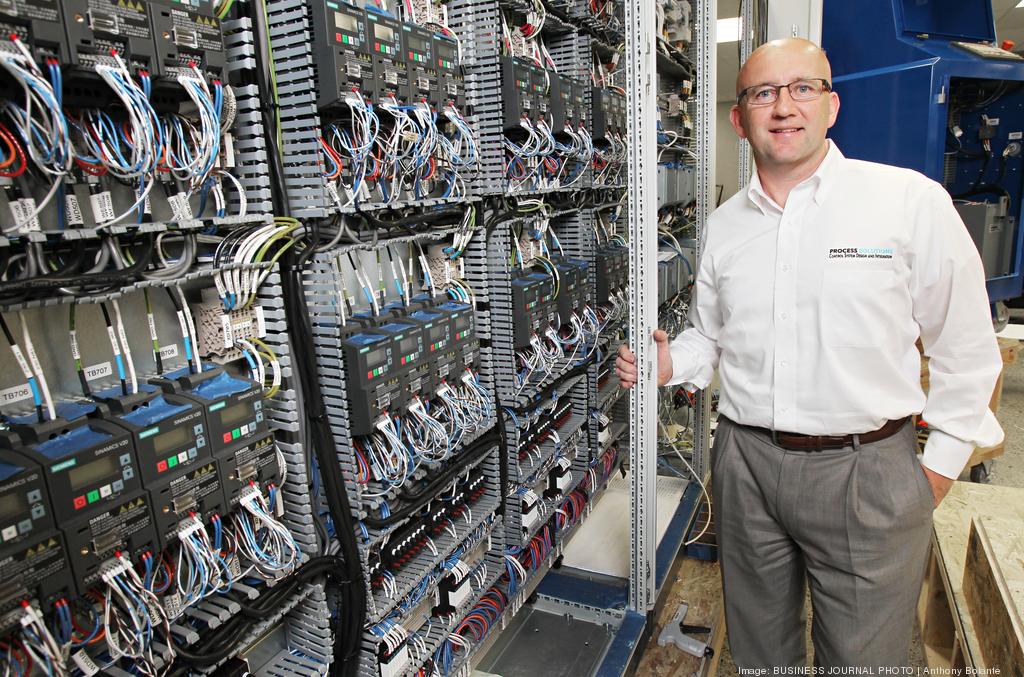

System Reliability Is Too Important To Settle For Just Any Integrator

Process Solutions understands that system downtime leads to reduced production capacity, a hassle for operators to diagnose and repair problems, and lost revenue for our clients. We take these risks to heart and have established procedures for designing and manufacturing control systems with industry-leading quality to ensure that you receive a solution that you can rely on to keep your operations running smoothly.

By choosing Process Solutions for your project, you are electing to work with a team of highly trained engineers with hundreds of combined years of experience in designing, building, and implementing control systems across a broad range of industries. This experience enables us to accurately assess your application and recommend the optimal solution to meet your requirements while having the foresight to identify potential challenges and how to best overcome them.

By choosing Process Solutions for your project, you are electing to work with a team of highly trained engineers with hundreds of combined years of experience in designing, building, and implementing control systems across a broad range of industries. This experience enables us to accurately assess your application and recommend the optimal solution to meet your requirements while having the foresight to identify potential challenges and how to best overcome them.

Your Success is Our Goal

Beyond providing quality control systems, our goal is to make you look like an all-star to your colleagues and management by helping you be successful on your project. We do everything possible to achieve that goal, including clearly defining the scope of work, gaining a complete understanding of your processes and needs, and adhering to our standards and procedures to ensure you receive a high-quality solution that meets or exceeds your requirements. In short, we strive to make executing your project a hassle free process that results in improving your operations… and maybe even getting you a promotion.

Detail Oriented

When details are overlooked, projects can go wrong, leading to unexpected change orders, schedule delays, and extra expenses. We take the necessary steps to avoid these issues by diligently reviewing project documents and specifications, regularly communicating with our clients, and following established procedures to ensure we don’t miss important details. Through our detail-oriented approach, we have earned our clients’ trust, resulting in the majority of our projects coming from repeat business.

Professionalism & Responsiveness

We approach every project with a professional attitude that reflects our level of expertise, experience, and capabilities. Whenever you interact with a Process Solutions representative, you will be treated with courteousness and care, while receiving knowledgeable information that assists you with your goals. Additionally, we do our best to reply to all correspondence quickly and will keep you informed throughout the entire course of your project. Above all else, you will never be left wondering how your project is progressing or questioning what exactly we are providing.

Qualified & Well-Resourced Team

Process Solutions employs over 50 control systems engineers and over 50 control panel technicians. In addition, Process Solutions employs Professional Engineers certified in the State of Washington, as well as multiple licensed electricians. Several of Process Solutions’ engineers hold Siemens, Rockwell, or Wonderware certifications in PLC and HMI programming, as well as SCADA development and motion control systems. To stay up-to-date with current technologies and to maintain their qualifications, Process Solutions often sends engineers to training courses or provides internal training conducted by Senior Engineering staff and upper-management.

Established Procedures To Keep You On-Schedule & On-Budget

We follow an established set of methods and procedures to ensure consistent quality, prevent delays or miscommunications, and successfully execute projects. Our procedures start from the initial contact with a prospective client and continue through delivery, system start-up, and post-project services. These procedures include scheduled kick-off meetings to comprehensively define the project scope and client requirements, as well as to establish a timeline and project schedule. Additionally, we utilize a project management application for team collaboration, work progress tracking, and to ensure no details are overlooked. During the engineering phase of a project, multiple design reviews are conducted by a Senior Engineer to check for compliance with standards and the project requirements. Finally, we perform panel inspections at various points during production to ensure quality and UL compliance, as well as to verify the functionality of all components and programs.

Engineering Expertise

Our engineering team has extensive experience implementing control systems that utilize hardware and software components from virtually all major manufacturers. This experience enables us to make recommendations on the technologies that will be best suited for your application. In addition, our engineering team has a breadth of capabilities from electrical design and software development, to industrial robot programming and IIOT system integration.

Capacity & Tooling

Our 30,000 sq. ft. engineering and manufacturing headquarters facility and additional 5,000 sq. ft. manufacturing facility provide us with the capacity to execute any size project while adhering to strict schedule requirements. Our automated tooling, which includes a CNC machine utilizing AutoCAD files for precision enclosure and back panel milling, as well as our engraving machine for device label and lamicoid production, enables us to streamline panel build times while providing repeatable quality on every project.

Proven Track Record

Process Solutions has successfully completed thousands of projects over the company’s 34-year history, which has resulted in numerous repeat clients, long-standing relationships with multiple OEM partners, and mutually supportive partnerships with industry-leading manufacturers, including Rockwell Automation (Recognized Systems Integrator), Siemens (Solution Partner), and Wonderware (Certified Systems Integrator). Process Solutions was selected for each of these manufacturer’s programs after consistently demonstrating a high level of proficiency in implementing their hardware and software products in our systems, in addition to our reputation and standing in the marketplace.

Thorough Documentation

Documentation is an important aspect of every project that is often overlooked or poorly developed. At Process Solutions, we pride ourselves on delivering thorough documentation that provides complete system detail to make operating, maintenance, and troubleshooting more efficient. Our documentation capabilities include panel layout drawings, wiring schematics, network drawings, P&ID diagrams, software design, sequence of operations, functional specs, FAT/SAT manuals, O&M manuals, certificates of conformity, certificates of origin, and FDA level drawings.

We'll Figure It Out

Process Solutions’ unofficial motto is that we’ll figure it out, meaning when faced with a challenge, we take a level-headed approach, apply our proven methods, and lean on our hundreds of combined years of controls and automation experience, to develop a solution that meets your goals and achieves the functionality you require with the level of quality you expect.

Rockwell Automation

System Integrator

Partner

Siemens

Solution Partner

Automation

Aveva

Certified

Systems Integrator

Ignition

Registered System

Integrator

Let's Get Started.

Send us your project information and we will be in contact with you shortly to discuss your requirements.